Our Services

Turbine Rebuilds

What is a Highspeed Turbine Rebuild?

Turbine Replacements

When and Why to replace the entire turbine.

When the chuck mechanism becomes worn to the point that burs are slipping out of the handpiece, its time to replace the turbine. There are other tell tale signs that its time to replace the entire turbine such as noise and possibly vibration felt during use. We keep records of the repairs on your handpieces and many times the length of time the turbine has been in service can determine that it is time for a turbine replacement. Our goals are to save you expense and downtime.

Slow Speed Repairs

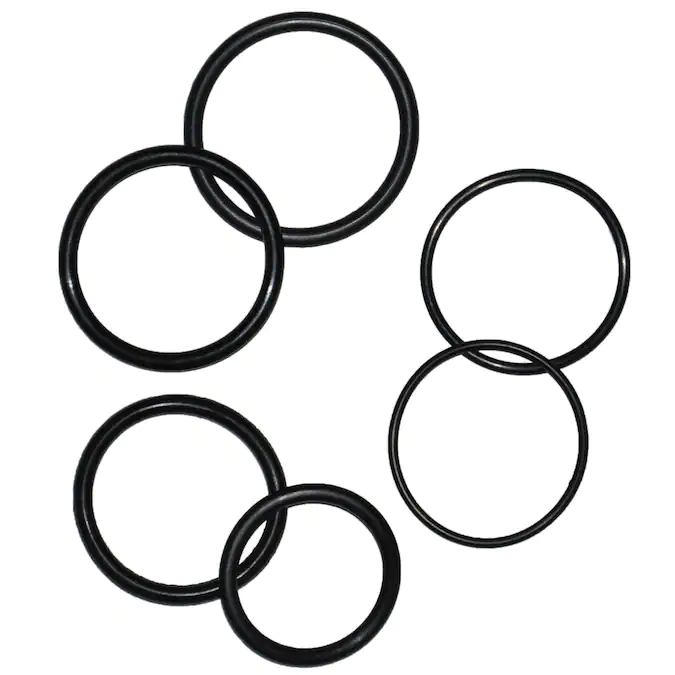

O-Rings

O-Rings aren’t something you think about everyday but there could be up to 10 O-Rings in one handpiece and up to 6 on the handpiece coupler. All O-Rings wear out after a period of time and need to be replaced. The O-Rings that support the turbine in the handpiece are the most critical and need replaced most frequently. To ensure proper operation of your couplers it is recommended that coupler O-Rings be replaced every 6 months. Many of the internal O-Rings of a handpiece can last for years with proper maintenance and lubrication. The internal O-rings mostly act as seals and with the expansion and contraction caused by sterilization they break down as well. Typical conditions you may notice because of internal O-ring breakdown are loss of power, water leaking from the back of the handpiece and poor water spray function at the head of the handpiece.

Handpiece Lubrication

Warranty

We offer a 6 month warranty for all repairs and on the sale of most new handpieces. All of our repairs and sales are tracked by identification on the handpiece and the customer. If we see failures due to negligence the warranty will be at our discretion.

Fast Turnaround

RECEIVE YOUR ITEMS QUICKLY